MENUMENU

- Products

-

-

Cast Resin Transformers

New generation dry type transformers, maintenance free, safe, reliable and ecological products

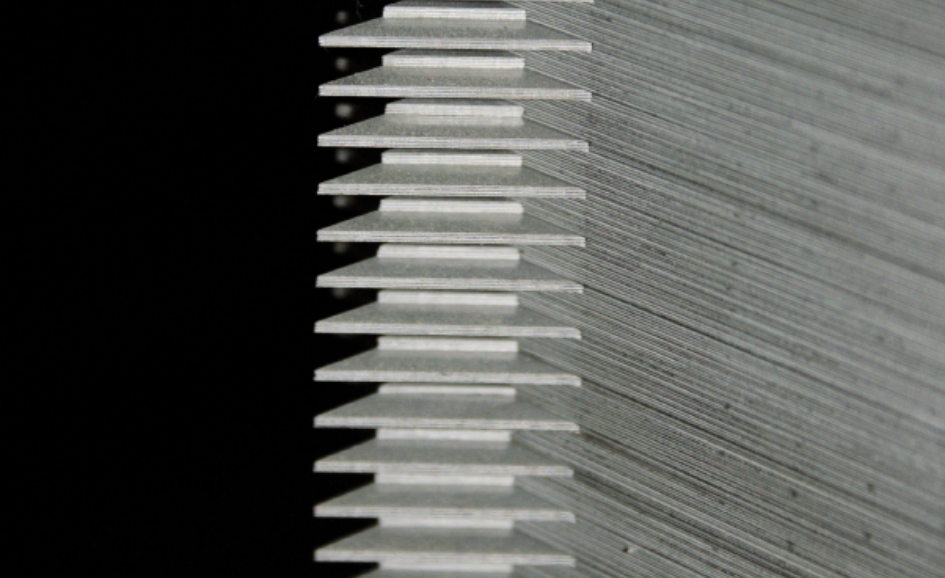

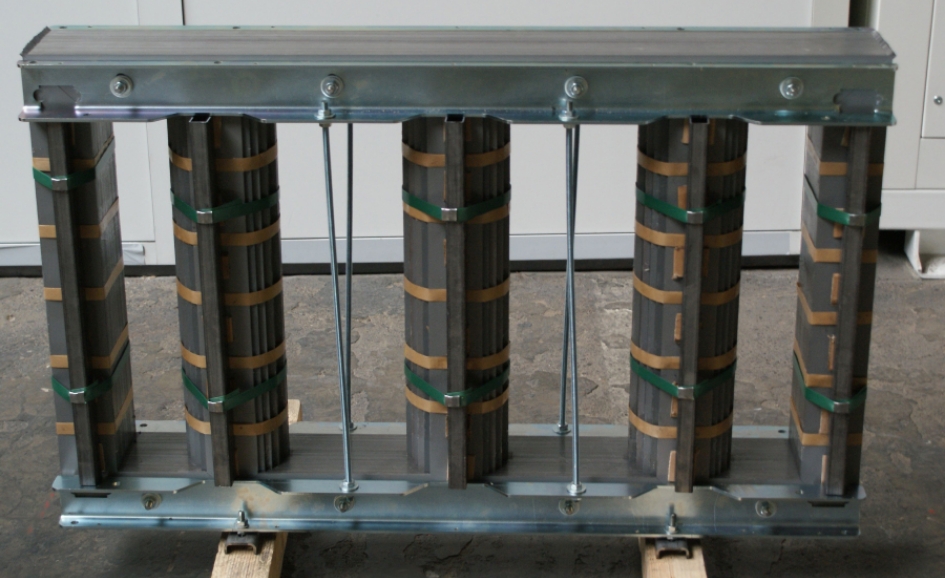

Magnetic Core

Excellent magnetic and electrical performace, extremly low losses, customized solutions

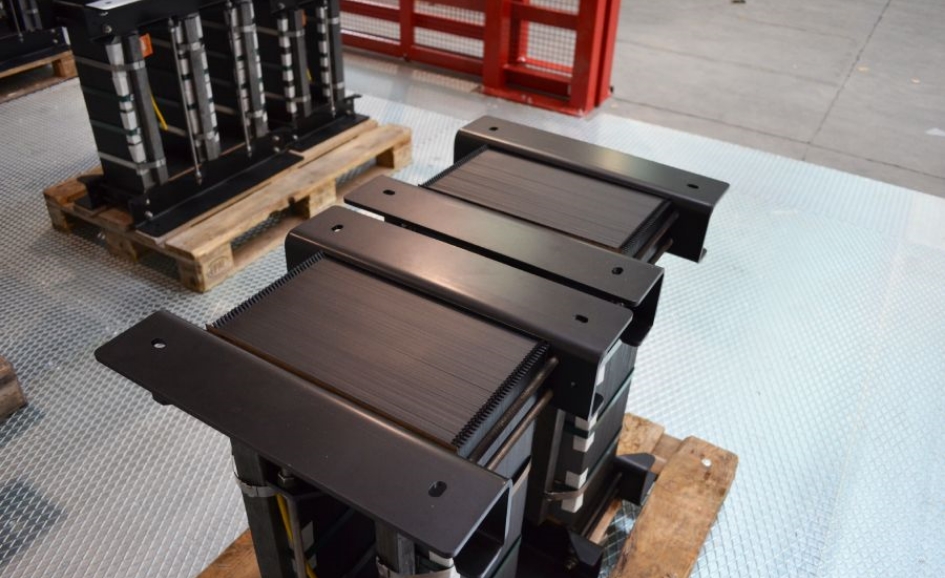

Accessories

Additional equipment to complete your cast resin transformer. Transformer fans, anti-vibration pads, protection relays

-

- Service

- About us

- References

- Download

- Blog

- Contact us